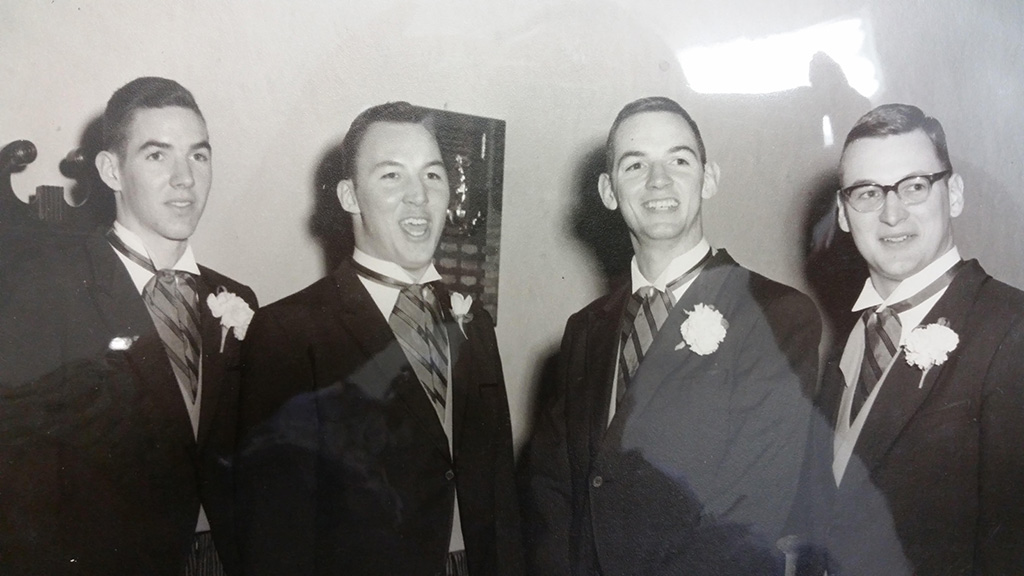

Brothers Jim, Tim, Pat & Joe Monahan

Handles, Inc. and the Changing Handle Market

In 1972, Jim became the second son, of Thomas Monahan Jr. to join the company. Jim took the responsibility for The Monahan Company’s growing handle business.

“We’d been brokering handles under The Monahan Company name, buying and reselling handles from domestic suppliers. In the early 70’s, when some of the imports of raw materials became available, it put us in the ballgame,” Jim said. “We could then go overseas and buy material rather than having to process it here domestically. Dowels came in already processed. That made it advantageous for us to go into handles, forming Handles, Inc. as a division of The Thomas Monahan Company.

“It has been an interesting business. Dealing in wood is very similar to dealing in broomcorn. It is a natural product that grows every year. In broomcorn, you are sometimes operation at the whim of Mother Nature when you take into account outside things like the amount of rain the growing areas receive. In the wood industry, we are a low-end user, so we are kind of at the mercy of the total wood market. A number of environmental concerns have been emphasized in recent years, and we are all involved in and impacted by reforestation projects, so this is a complex business, much like broomcorn.”

Ramin wood from Malaysia and Indonesia was the wood of choice for the industry until the green movement basically shut down the Ramin supply.

In 1985, Handles, Inc. began pursuing the new technologies that made metal handles a feasible product. It was slow going, at first, Jim said when the company started offering the metal products. It was a time when the metal handles cost roughly the same as the wooden handles, yet wood was still readily available to the consumer.

The metal handles struggled a little bit for a few years to find their place and be accepted in the market.” Jim said. “Later on, in the ‘80’s and early ‘90’s, we ran into a few shortages of pine. As wood became harder to get, we had some customers change to metal. Once some people switched to metal, they didn’t go back.” Metal handles are consistent and made to an acceptable tolerance and are independent of weather fluctuations, and are the standard for the household market. Handles Inc invested heavily in metal handle equipment – eventually running 4 lines of metal handles – producing 20,000,000 handles per year, making them the largest producer of metal handles in the USA. They sold this plant to FIMM in 2009.

Brothers Jim, Tim, Pat & Joe Monahan

Wood is still popular. In many instances, wood is the best application for a handle. “There are 54 and 60-inch metal handles available that will switch some of the demand over to metal from wood, and it is going to help stabilize the market. In some of the traditional industries, such as the janitorial supply and industrial supply market, people are still going to want wood handles.”

“These days, corporations have taken over from the smaller manufacturer as the dominant force in the industry, and the purchasing agents for the corporations want to be able to call for supplies on a Monday and have them delivered on a Thursday,” Jim said. “They don’t want to hear about the rainy season in Honduras or something like that that’s causing problems getting the wood raw material. Purchasing agents are very, very busy, overworked, and overloaded with items they are buying. If they can find a good consistent supplier, that’s what they want. And that is what we strive every day to provide. The Thomas Monahan Company merged its wood handle business, forming Whitley-Monahan Handle and Jim is co-owner and head of sales for this company today.